Project Description

POWER MANAGEMENT AND REGULATING SYSTEM NOVATRACE

The NOVATRACE electronic regulator has been specially developed for regulation of your electrical tracing installations using self-regulating heating cables. An integrated starting current absorber allows gradual power-up without over-calibration of thermal protections being necessary unlike the conventional control systems.

Operation mode

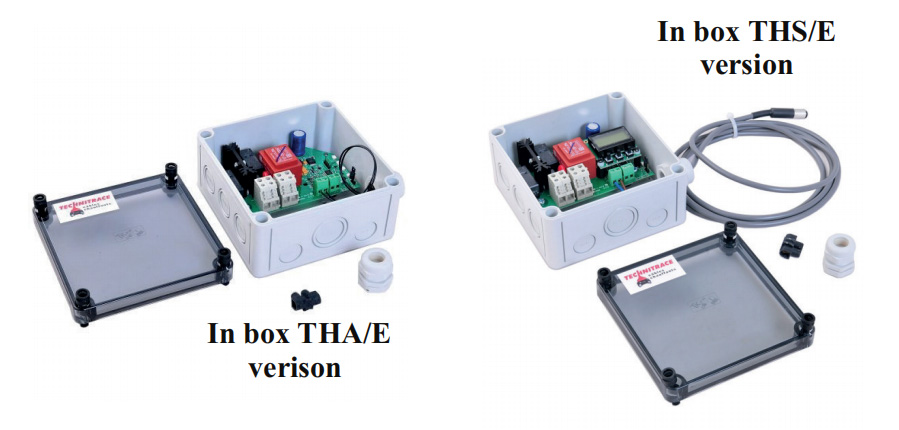

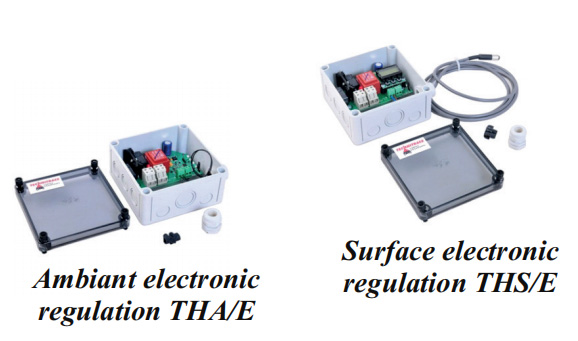

The NOVATRACE regulator can be configured

– as a ambiant controller: THA/E version (ambiant temperature sensor)

– as a surface regulator: THS/E version (surface temperature sensor)

Control modes

The regulation can be done according tow different control modes

– ON/OFF mode in the case of surface regulation with temperature sensor directly in contact with the pipe.

– chrono-proportional mode : power ON/OFF time ligne sequences according to the evolution of the ambient temperature over time Q=F(Ta) and regardless of the hydraulic regime of the pipe

ENERGY CONTROL

At any time, the delivered power is in perfect harmony with the real need for the installation. The NOVATRACE system therefore allows perfect control of energy (savings of almost 50%), as well as temperature of maintenance which remains perfectly constant throughout the installation and this whatever the hydraulic regimes of the pipes.

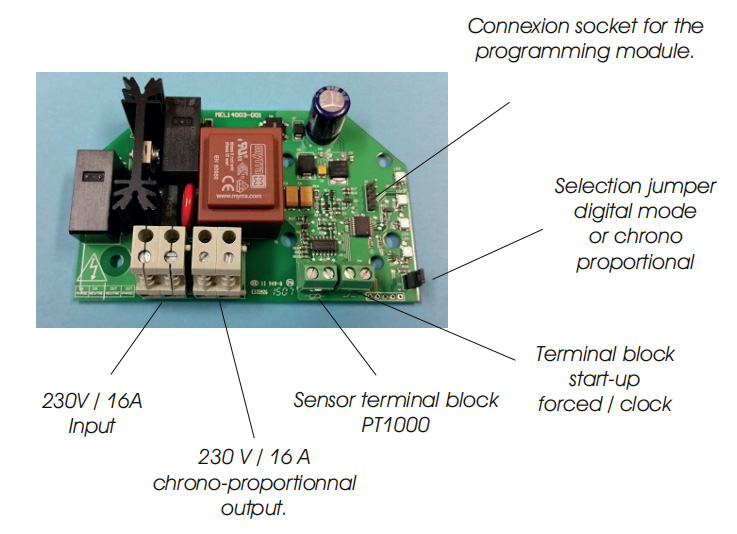

The NOVATRACE card

Main advantages

– Ambient temperature sensor molded in PE M20.

– PT1000 temperature sensor offset by 2000 mm or more on request.

– range of use : 5°C to 120°C.

– works blindly (without visual console).

– mini programming console with digital display (option).

– energy saving because the power delivered over the entire

network is the thermal image of the real calorific need.

– current absorber at start-up for self-regulating cables.

– 230 V / 50-60Hz power supply.

– under BJK/S IP 66 enclosure: dim 125*125*85 mm.

– elimination of the risks of overheating on the right of the dead arms.

– scalable system: possibility of changing the P0 and Tas parameters,

differential, time base, current absorber, …

– factory pre-settings: P0°C = 65% and TAS = 5°C.

– forced start on terminal for preheating.